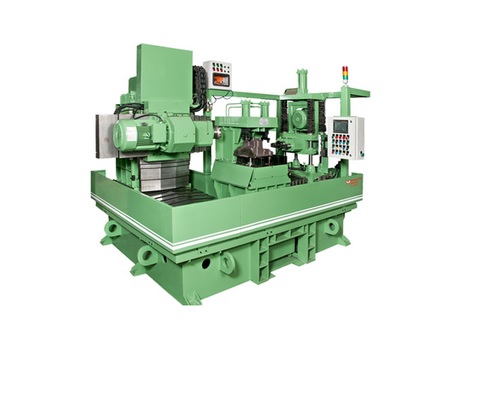

Special Purpose Machine Manufacturers in Chennai

Special Purpose Machine Manufacturers in Chennai

We are a prestigious company in Chennai in the field of Special Purpose Machine Manufacturers. For any questions contact us.

Special purpose machines (SPM) are those machines that are not available off the shelf and these are not covered in standard manufacturing progression; these are designed and custom-made as per the customer-specific requirements. A big portion of the special purpose machines is focused on automated trimming or inspection, and assembling operations.

Advantages of SPM

- Increase in productivity

- Less time consuming

- Decreases maintenance and servicing cost

- Increase in production rate and tool life

- Less complicated

- High durability

- Operative in mass production

Types of Special Purpose Machine

Turning machines

The engine lathe, as the flat metal-turning machine is usually called, is the most significant of all the machine tools. It is regularly deliberated the father of all other machine tools because many of its important mechanical elements are integrated into the design of other machine tools.

Shapers and planers

Shaping and planning processes involve the machining of smooth surfaces, furrows, shoulders, T-slots, and angular surfaces with single-point tools. The biggest shapers have a 36-inch cutting lash and can machine parts up to 36 inches long. The cutting tool on the shaper hesitates, cutting on the forward lash, with the work piece feeding automatically towards the tool during each return lash.

Planning machines perform the same operations as shapers but can machine longer work pieces. Some planners can machine parts up to 50 feet long. The work piece is mounted on a reciprocating table that moves the work piece beneath a cutting tool.

Milling machines

A milling machine scratches metal as the work piece is fed against a rotating cutting tool called a milling cutter. Shears of many shapes and sizes are available for a varied variety of milling operations. Milling machines cut flat surfaces, furrows, shoulders, inclined surfaces, unites, and T-slots.

Grinding machines

Grinding machines eliminate small chips from metal parts that are carried into contact with a rotating abrasive wheel called a grinding wheel or a rough belt. Grinding is the most accurate of all of the basic machining progressions.

Drilling machines

Drilling machines, also called drill presses, cut holes in metal with a screw drill. They also use a range of other cutting tools to achieve the following basic hole-machining processes: reaming, boring, counterboring, countersinking, and tapping internal threads with the use of a tapping attachment.

Visit us in Google Maps

Our Related Products

Fixture Manufacturers in Chennai

Material Handling Equipment Manufacturers in Chennai

Pallet Manufacturers in Chennai

Special Purpose Machine Manufacturers in Chennai

Warehouse Rack Manufacturers in Chennai

Leave a Reply

Want to join the discussion?Feel free to contribute!